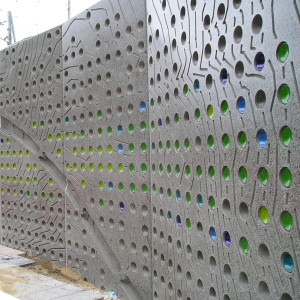

Honing and polishing are two individual surface treatments that can also be combined as a two-step process to give a superior surface similar to natural polished stone or granite. Honing refers to the removal of the outer surface of concrete by using a grinder that has a coarse abrasive effect, exposing the aggregate in the concrete and giving a flat level surface.

Polishing is a similar process taking the finish to the next level, which uses finer abrasive materials to take a finer cut from the concrete. The result is a very smooth, shiny finish. Both processes use lubrication to ensure gouging and scratching don’t occur on the surface. Aggregates used for honed and polished surfaces are chosen for colour, durability and ability to hold a polish. Polished surfaces shed water and dirt easily and have minimal surface absorption, and therefore require minimal ongoing maintenance. Polishing and honing of curves and small recesses are possible but the shape of the element must be considered for this surface, along with the capability of the individual supplier.